The Grain Trade under the Dubrovnik Republic

Grain was a vital commodity for the city, and its production, storage, and sale was tightly controlled by the government, with a view both to the immediate needs of the community and in the possible event of either a siege or a year of poor harvest. According to the Statute, the granary clerks were required to record the amounts of grain delivered to the granary, and also to levy the proportion that was due to the state. It was a punishable offense for anyone, resident or foreigner, to sell grain anywhere but to the granary without the Rector’s permission. The best-known granary, the Rupe (hole, or pit), was constructed between 1542 and 1590 and consists of 15 deep, dry storage pits that were excavated from the rock. These pits were constructed on two levels with a system of openings and chutes that could carry the grain from a higher to a lower level. The mocatik was the proportion of grain that was due to the Archbishop, the Rector, and the sacristan of the Cathedral. The Rector also had the right to have the grain for his private use milled without charge. There was an office in the Rector’s Palace that could issue vouchers to the poor and needy of the town that could be redeemed for grain from the granary, sometimes treated as a loan, but sometimes also as a gift from the commune. Nowadays the Rupe is used as an ethnographic museum.

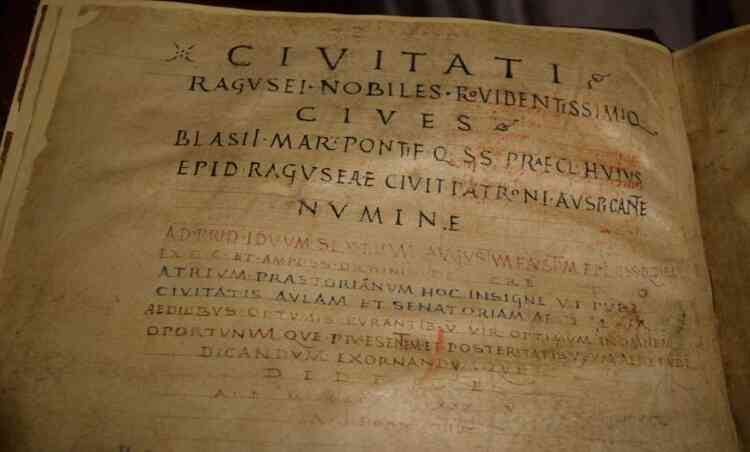

The statute of Dubrovnik, drawn up in Latin in 1272.

Salt Production

The strong economy of Dubrovnik, based mostly on trade and shipbuilding, also benefited greatly from its monopoly of trade in salt. Many laws relating to the production, marketing, storage, and trading of salt were included in the Statute. All officials involved in administering the salt trade were obliged to swear an oath on the Statute that they would keep true accounts and abide by these regulations. When in 1333. Dubrovnik expanded its territory to include the Pelješac peninsula, its production of salt was much increased since the town of Ston was a principal producer. The salt pans of Ston consist of 52 shallow pools that can be flooded with seawater at high tide and closed to allow the deposit of salt by evaporation. The process is very much dependant on weather conditions, the collection being necessary before the rain. There was thus a statutory obligation on the local people to come and assist at the time when the salt was collected Today the production of salt in Ston continues by the same basic methods, 90% of the product being used for industrial purposes. There is a plan to line the salt pans with granite to improve production and quality, and to include the salt works in the itinerary of visitors already attracted to Ston for its famed oysters and mussels.